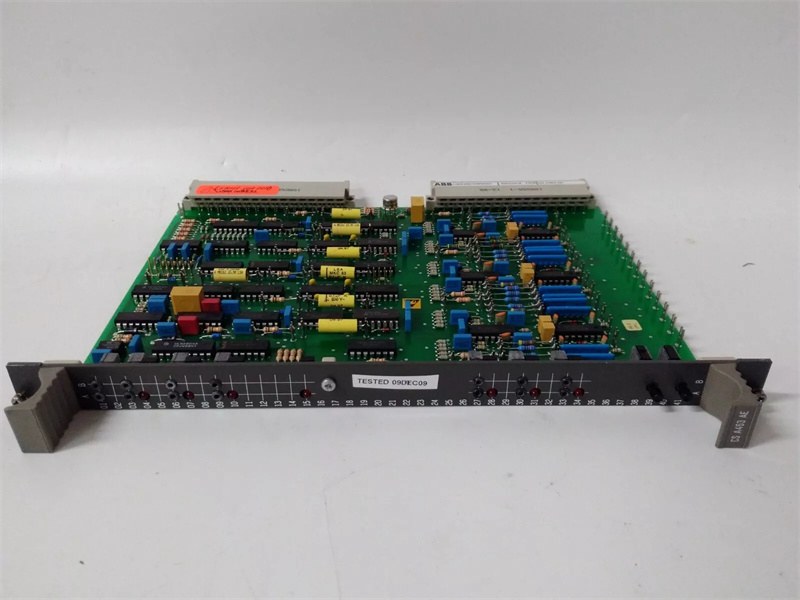

以下是对ABB CSA463AE通讯网关控制板:

一、技术规格

核心功能

高精度监测:实时采集设备运行数据(如温度、电压、转速),支持故障预警。

远程通信:支持以太网、Modbus、Profinet等协议,实现与SCADA系统或云平台的数据交互。

环境适应性:

工作温度范围:-40℃至55℃

防护等级:IP54(防尘、防水溅)

自然冷却设计,无需额外散热设备。

硬件参数

输入/输出:支持数字量(DI/DO)、模拟量(AI/AO)及组合信号(GI/GO)。

通信接口:内置以太网口,支持RS-232/RS-485扩展。

电源要求:220V交流供电,功率≤1200W。

二、配置指南

基础配置流程

网络设置:

通过示教器进入控制面板 > 配置 > 网络,设置IP地址、子网掩码。

示例:若连接PLC,需确保双方IP在同一网段(如机器人IP设为192.168.1.100,PLC设为192.168.1.200)。

I/O信号映射:

在配置 > I/O系统中定义信号名称(如Motor_Start)及类型(数字/模拟)。

注意:信号名称需唯一,首字符为字母,长度≤16字符。

高级功能配置

通信协议选择:

在通信设置中选择协议(如Profinet需配置设备名称及GSD文件)。

安全参数:

配置访问权限(如Access Level设为Write允许外部设备修改参数)。

三、兼容性

系统兼容性

支持设备:兼容ABB AC800M系列DCS系统、主流PLC(如西门子S7-1500)及工业机器人控制器。

软件工具:需使用ABB官方软件(如RobotStudio、Control Builder)进行编程和调试。

物理接口

电气接口:支持M12连接器(D编码)或RJ45以太网口。

机械安装:采用导轨安装或面板固定方式,适配标准控制柜。

四、故障排除

常见通信问题

故障现象:示教器显示“通信超时”。

排查步骤:

检查网线是否松动,更换备用网线测试。

确认双方IP地址无误(避免冲突)。

重启控制板及外部设备,观察是否恢复。

硬件故障处理

LED状态:

若ERROR灯常亮,可能为内部保险丝熔断,需联系ABB售后更换。

信号干扰:

检查电缆屏蔽层是否接地,避免与高功率电缆并行布线。

五、应用场景

工业自动化:用于生产线状态监控(如电机温度、压力传感器数据采集)。

能源管理:集成到智能电网中,实现远程设备控制(如变频器启停)。

机器人控制:作为ABB机器人与MES系统的通信枢纽,传输生产数据。

The following is the ABB CSA463AE communication gateway control board:

1、 Technical specifications

Core functions

High precision monitoring: Real time collection of equipment operation data (such as temperature, voltage, speed), supporting fault warning.

Remote communication: Supports protocols such as Ethernet, Modbus, Profinet, etc., to achieve data exchange with SCADA systems or cloud platforms.

Environmental adaptability:

Working temperature range: -40 ℃ to 55 ℃

Protection level: IP54 (dustproof, waterproof splash)

Natural cooling design, no additional heat dissipation equipment required.

Hardware parameters

Input/Output: Supports digital signals (DI/DO), analog signals (AI/AO), and combined signals (GI/GO).

Communication interface: Built in Ethernet port, supporting RS-232/RS-485 expansion.

Power requirement: 220V AC power supply, power ≤ 1200W.

2、 Configuration Guide

Basic configuration process

Network settings:

Go to Control Panel>Configuration>Network through the teaching pendant, and set the IP address and subnet mask.

Example: If connecting to a PLC, it is necessary to ensure that both IP addresses are in the same network segment (such as setting the robot IP to 192.168.1.100 and the PLC to 192.168.1.200).

I/O signal mapping:

Define signal names (such as Motor_Start) and types (digital/analog) in Configuration>I/O System.

Attention: The signal name must be unique, with a letter as the first character and a length of ≤ 16 characters.

Advanced feature configuration

Communication protocol selection:

select the protocol in the communication settings (such as Profinet, which requires configuring the device name and GSD file).

Security parameters:

Configure access permissions (such as setting Access Level to Write to allow external devices to modify parameters).

3、 Compatibility

system compatibility

Supporting devices: compatible with ABB AC800M series DCS systems, mainstream PLCs (such as Siemens S7-1500), and industrial robot controllers.

Software tools: ABB official software (such as RobotStudio, Control Builder) is required for programming and debugging.

physical interface

Electrical interface: Supports M12 connector (D code) or RJ45 Ethernet port.

Mechanical installation: using guide rail installation or panel fixing method, suitable for standard control cabinets.

4、 Troubleshooting

Common communication issues

Fault phenomenon: The teaching pendant displays "communication timeout".

Troubleshooting steps:

Check if the network cable is loose and replace it with a spare cable for testing.

Confirm that both parties' IP addresses are correct (to avoid conflicts).

Restart the control board and external devices and observe if they are restored.

Hardware fault handling

LED status:

If the ERROR light stays on, it may be due to a blown internal fuse, and ABB after-sales service needs to be contacted for replacement.

Signal interference:

Check if the cable shielding layer is grounded and avoid parallel wiring with high-power cables.

5、 Application scenarios

Industrial automation: used for monitoring the status of production lines (such as collecting data from motor temperature and pressure sensors).

Energy management: integrated into the smart grid to achieve remote device control (such as frequency converter start stop).

Robot control: As the communication hub between ABB robots and MES systems, it transmits production data.

| PM860AK01 | 3BSE066495R1 |

| PM862K01 | 3BSE076940R1 |

| PM862K02 | 3BSE081636R1 |

| PM866AK01 | 3BSE076939R1 |

| PM866AK02 | 3BSE081637R1 |

| PM891K01 | 3BSE053241R1 |

| PM891K02 | 3BSE053242R1 |

| SB822 | 3BSE018172R1 |

| PM857K01 | 3BSE088385R1 |

| PM857K02 | 3BSE088386R1 |

| PM863K01 | 3BSE088381R1 |

| PM863K02 | 3BSE088382R1 |

| PM867K01 | 3BSE076355R1 |

| PM867K02 | 3BSE081638R1 |

| SM811K01 | 3BSE018173R1 |

| SM812K01 | 3BSE072270R1 |

| ABB | PM633 3BSE008062R1 |

| EMERSON | VE3007 KJ2005X1-BA2 |

| B&R | 4PP065.0571-X74F |

| VIBRO | CPU-M |

| VIBRO | OC8T |

| VIBRO | IOC-N |

| VIBRO | MPC4 |

| VIBRO | RPS6U |

| VIBRO | XIO16T |

| METSO | A413240 |

| SCHNEIDER | BMEH584040S |

| ODULE PIB | 315B-143400305 |

| ABB | 3BHB007209R0102 |

| ABB | 3BHB007211R0101 |

| ABB | 3BHE006412R0101 |

| ABB | 3BHE009017R0102 |

| TRACO POWER | TIS600-128-RED-GE |

| GE | IS420ESWAH2A |

| GE | IS220PDIOH1A |

| GE | IS220PTCCH2A |

| GE | IS220PDIAH1A |

| A-B | 80190-580-01-R |

| A-B | 80026-508-03-R |

18030183032