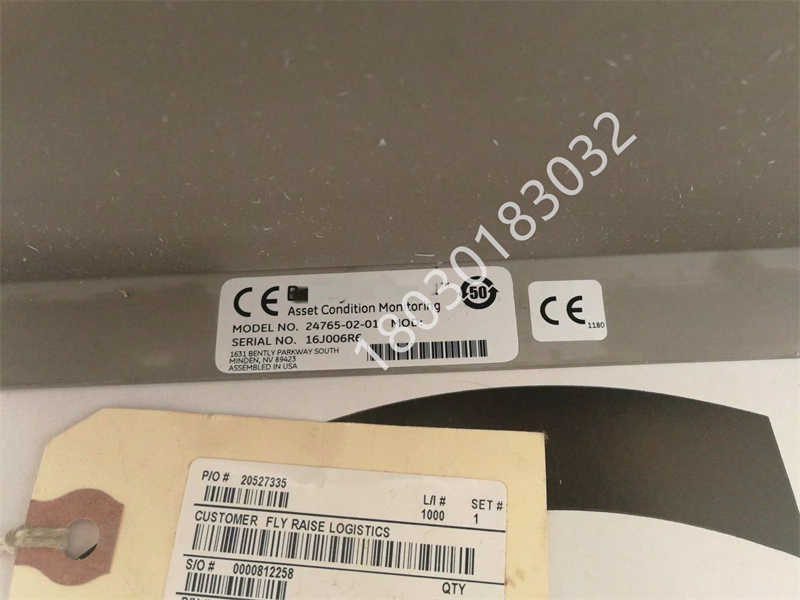

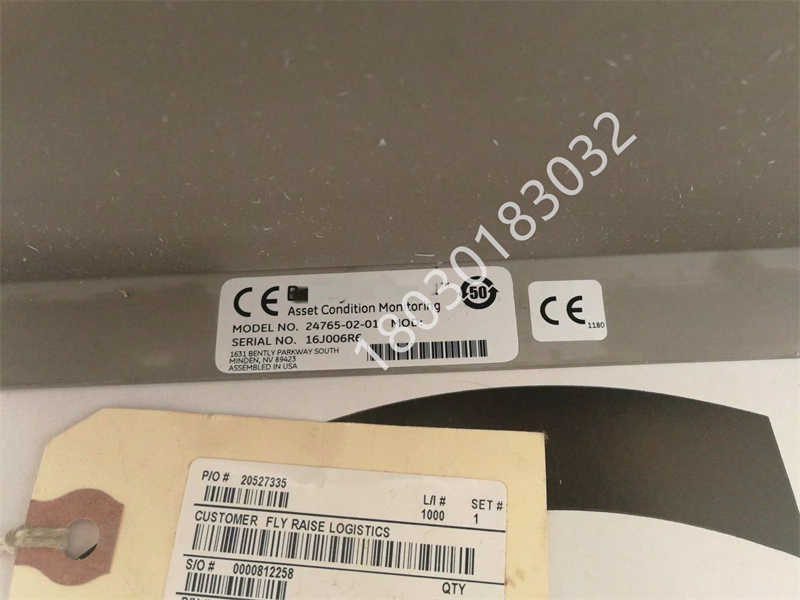

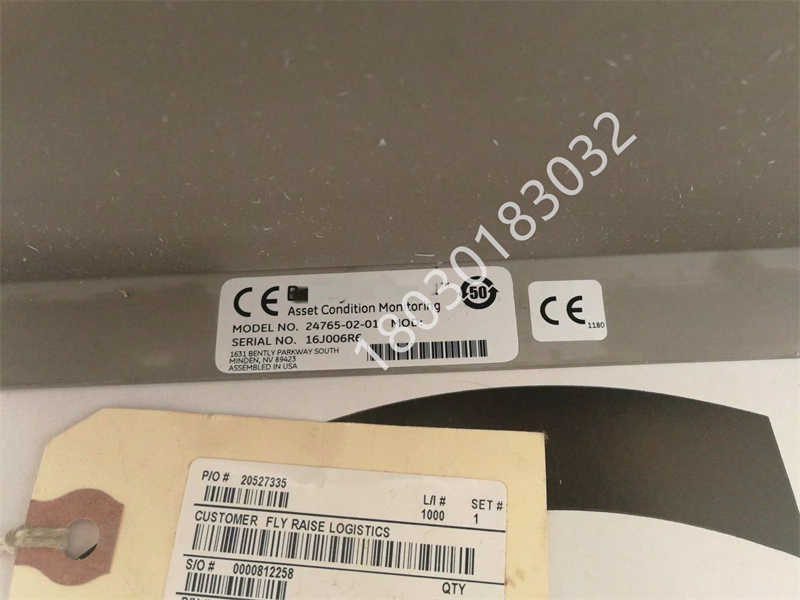

BENTLY 24765-02-01 本特利传感器是一款专为工业设备状态监测设计的高精度传感器,广泛应用于汽轮机、压缩机、风机等旋转机械的振动、位移、膨胀等参数的实时监测。

一、产品特点

高精度测量

采用线性可变差动变压器(LVDT)技术,线性范围可达 50.8mm,分辨率高,确保测量数据的准确性。

电气比例系数为 0.404V/mm,输出信号稳定,抗干扰能力强。

宽温工作范围

工作温度范围为 -18°C 至 +71°C,适用于恶劣的工业环境。

坚固耐用设计

传感器配备防护罩,可有效抵御灰尘、油污和水汽的侵蚀,延长使用寿命。

结构紧凑,安装方便,适用于各种工业现场。

高可靠性和稳定性

满量程稳定性优于 0.125%,非线性误差小于 0.25%,温度系数为 0.05%/°C,确保长期运行的可靠性。

二、技术参数

参数 规格

电气比例系数 0.404V/mm

线性范围 50.8mm

工作温度 -18°C 至 +71°C

输出信号 电压信号(0-5V)

防护等级 IP65(防护罩)

安装方式 螺纹安装

重量 2.3Kg

三、应用领域

汽轮机监测:用于监测汽轮机机壳的热膨胀,防止因热应力导致的设备损坏。

压缩机监测:实时监测压缩机转子的振动和位移,确保设备安全运行。

风机监测:对风机的轴向位移和振动进行监测,提前预警潜在故障。

工业自动化:适用于各种旋转机械的状态监测和故障诊断。

四、安装与使用

安装位置

传感器应安装在设备的关键监测点,如机壳、轴承座或转子轴上,确保测量数据的有效性。

接线方式

按照传感器说明书连接电源和信号线,确保接线牢固,避免信号干扰。

调试与校准

安装完成后,需进行零位校准和灵敏度调整,确保测量数据的准确性。

日常维护

定期检查传感器的防护罩是否完好,清理灰尘和油污,确保传感器正常工作。

五、优势总结

高精度与稳定性:满足工业设备对高精度测量的需求。

宽温适应性:适用于各种恶劣环境,确保长期可靠运行。

易于安装与维护:结构紧凑,安装方便,维护成本低。

广泛应用:适用于汽轮机、压缩机、风机等多种工业设备。

六、注意事项

避免在强电磁干扰环境下使用,以免影响测量精度。

安装时需确保传感器与被测表面垂直,避免测量误差。

定期检查传感器的输出信号,发现异常及时处理。

BENTLY 24765-02-01 Bentley sensor is a high-precision sensor designed specifically for industrial equipment condition monitoring, widely used for real-time monitoring of vibration, displacement, expansion and other parameters of rotating machinery such as steam turbines, compressors, fans, etc.

CHARACTERISTICS

high precision measurement

Adopting linear variable differential transformer (LVDT) technology, the linear range can reach 50.8mm, with high resolution, ensuring the accuracy of measurement data.

The electrical proportional coefficient is 0.404V/mm, the output signal is stable, and the anti-interference ability is strong.

Wide temperature working range

The working temperature range is -18 ° C to+71 ° C, suitable for harsh industrial environments.

Durable and sturdy design

The sensor is equipped with a protective cover, which can effectively resist the erosion of dust, oil, and water vapor, extending its service life.

Compact structure, easy installation, suitable for various industrial sites.

High reliability and stability

The full-scale stability is better than 0.125%, the nonlinear error is less than 0.25%, and the temperature coefficient is 0.05%/° C, ensuring the reliability of long-term operation.

2、 Technical parameters

Parameter specifications

Electrical proportional coefficient 0.404V/mm

Linear range 50.8mm

Working temperature -18 ° C to+71 ° C

Output signal voltage signal (0-5V)

Protection level IP65 (protective cover)

Installation method: threaded installation

Weight 2.3Kg

3、 Application Fields

Turbine monitoring: used to monitor the thermal expansion of the turbine casing and prevent equipment damage caused by thermal stress.

Compressor monitoring: Real time monitoring of the vibration and displacement of the compressor rotor to ensure safe operation of the equipment.

Fan monitoring: Monitor the axial displacement and vibration of the fan to provide early warning of potential faults.

Industrial automation: suitable for condition monitoring and fault diagnosis of various rotating machinery.

4、 Installation and use

Installation position

Sensors should be installed at key monitoring points of the equipment, such as the casing, bearing seat, or rotor shaft, to ensure the validity of measurement data.

Connection

Connect the power and signal wires according to the sensor manual, ensuring that the wiring is secure and avoiding signal interference.

Debugging and Calibration

After installation, zero calibration and sensitivity adjustment are required to ensure the accuracy of measurement data.

Routine maintenance

Regularly check whether the protective cover of the sensor is intact, clean dust and oil stains, and ensure that the sensor is working properly.

5、 Summary of Advantages

High precision and stability: meet the needs of industrial equipment for high-precision measurement.

Wide temperature adaptability: Suitable for various harsh environments, ensuring long-term reliable operation.

Easy to install and maintain: compact structure, easy installation, low maintenance cost.

Widely applicable: Suitable for various industrial equipment such as steam turbines, compressors, fans, etc.

6、 Precautions

Avoid using in strong electromagnetic interference environments to avoid affecting measurement accuracy.

During installation, it is necessary to ensure that the sensor is perpendicular to the surface being measured to avoid measurement errors.

Regularly check the output signal of the sensor and promptly handle any abnormalities found.

| FOXBORO | P0924WV |

| FOXBORO | P0926GU |

| NI | pxi-8108 |

| Honeywell | FC-PSU-UNI2450U |

| Honeywell | DC-PDOD51 |

| Honeywell | DC-PDIL51 |

| Honeywell | DC-TDOD51 |

| Honeywell | DC-TDIL51 |

| A-B | 1769-L36ERM |

| ABB | PM5630-2ETH |

| ABB | CI854AK013BSE030220R1 |

| NI | PXI5122 |

| ABB | DSQC6633HAC029818 |

| ABB | SPAU140C |

| A-B | 1715-OF8I |

| FOXBORO | FBM230 |

| YOKOGAWA横河 | CP471-00 |

| ABB | EL3020 |

| Rexroth | VT-HNC100-1-23/W-08-P-0 |

| ABB | 3BHB006621R0103UAC375AE103 |

| ABB | 3BHE004573R0043UFC760BE43 |

| ABB | 1TGE120028R0010 |

| A-B | 1756-OF8H |

| GE | IC697BEM731 |

| SCHNEIDER | BMXAMO0802 |

| GE | RS-FS-9001 |

| GE | IC698CRE030 |

| EMERSON | A6500-CC |

| A-B | 2094-BL50S |

| ABB | 1SVR040000R1700 |

| GE | IC755CSS12CDB |

| GE | IS420ESWBH2A |

| B&R | 8BVP0880HW00.004-1 |

| KOLLMORGEN | S406AM-CA |

| KOLLMORGEN | Servostar 403A-C |

| EMERSON | SE3008 |

| BENTLY NEVADA | 2300/20-00-01 |

| ABB | 3BHB004661R0101KUC711AE101 |

| ABB | 3BHE037864R1110 CVMI2B |

| WOODWARD | SPM-D118440-2165 |

| WOODWARD | 9907-014 |

主营产品,优势供应,充足库存 世界知名品牌的PLC 、DCS 系统备件 模块 Honeywell霍尼韦尔。Schneider施耐德。 艾默生EMERSON。XYCOM。 Woodward伍德沃德。西屋Westinghouse。 WEStation系统备件。英维思Triconex。 Motorola摩托罗拉。罗克韦尔Rockwell。 ABB。XYCOM。 本特利Bently。GE通用电气。Yaskawa安川。 Bosch Rexroth博世力士乐。 Yokogawa横河。Siemens(西门子)。 Reliance。Modicon莫迪康。

18030183032