EMERSON VE4003S2B1 艾默生模拟输入模块是一款专为工业自动化设计的高精度、高稳定性的模拟信号输入设备。以下是对该模块的详细解析:

The EMERSON VE4003S2B1 Analog Input Module is a highly accurate and stable analog signal input device designed for industrial automation. The following is a detailed analysis of the module:

I. Product overview

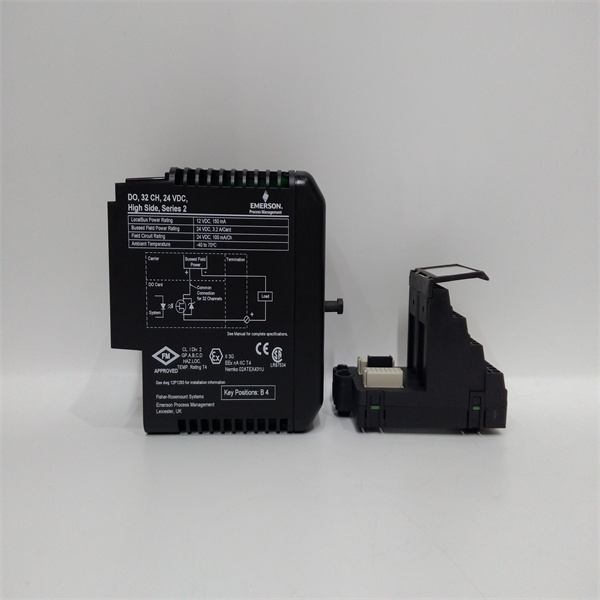

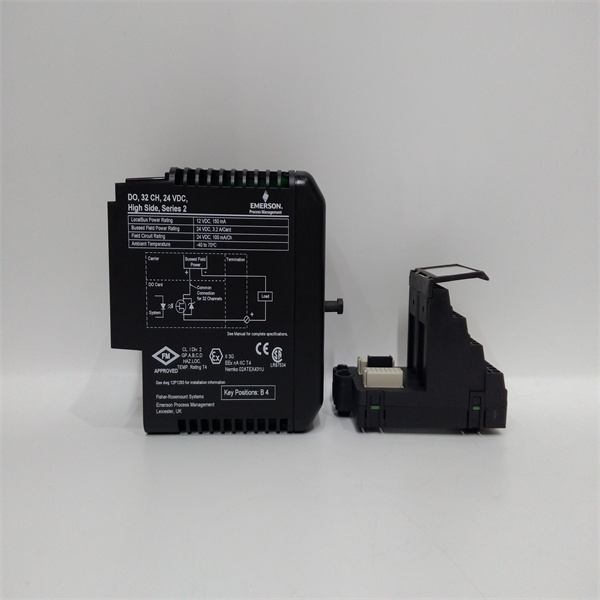

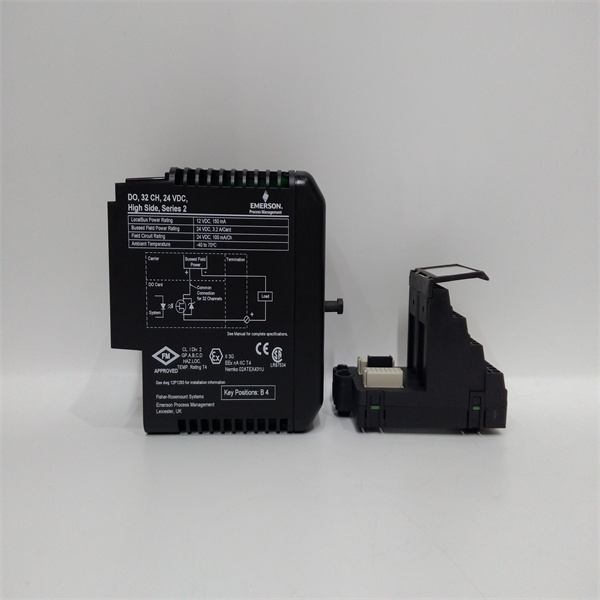

Make and Model: EMERSON/VE4003S2B1

Product type: Analog input module

Application: Compatible with DeltaV system, it is widely used in industrial automation control systems, such as production line control, mechanical equipment control, building automation, etc.

Two, the main characteristics

High accuracy and stability: The module is capable of receiving and processing high-precision analog signals to ensure data accuracy and reliability.

Multi-channel input: usually has multiple input channels (such as 8 channels), can receive multiple analog signals at the same time, improve the flexibility and efficiency of the system.

Support HART communication protocol: It can communicate with intelligent sensors with HART protocol to achieve remote monitoring and fault diagnosis.

Wide temperature and wide wet working range: can work normally in a wide temperature range (-40℃ to +70℃) and humidity range (5% to 95% relative humidity, no condensation), suitable for various industrial environments.

Modular design: Easy to install and replace, while providing detailed installation instructions and maintenance manuals to reduce maintenance costs.

3. Technical parameters

Input voltage range: 12-48VDC (may vary depending on model and configuration)

Output voltage range: 5VDC

Output current: Max. 10A

Efficiency: greater than 90%

Dimensions: 170mm x 105mm x 32mm

Weight: About 120g

Operating temperature: -20°C to +50°C

Storage temperature: -40°C to +70°C

Ambient humidity: 5% to 95% relative humidity (no condensation)

CPU: 32-bit RISC processor

Iv. Application scenarios

Production line control: In the automated production line, it is used to receive analog signals from various sensors (such as temperature, pressure, flow, etc.) to achieve real-time monitoring of the production process.

Mechanical equipment control: In mechanical equipment, it is used to receive feedback signals from various actuators to ensure accurate operation and fault diagnosis of mechanical equipment.

Building automation: In the building automation system, it is used to receive analog signals of environmental parameters (such as temperature, humidity, light, etc.) to achieve intelligent regulation and control of the building environment.

18030183032