GE美国IC694ALG392模拟输出模块是通用电气(GE)公司生产的PACSystems RX3i系列中的一个关键组件。该模块专为工业自动化设计,具有强大的模拟量输出功能,能够将数字信号转换为模拟信号输出,以精确控制外部设备或系统。以下是关于该模块的详细解析:

IC694ALG392模拟输出模块广泛应用于工业自动化领域,特别是在需要精确控制模拟量输出的系统中。它已被成功应用于数控机械、冶金、石油天然气、造纸印刷、纺织印染、电子制造、汽车制造、烟草、塑胶机械、发电厂、水利处理/环保、市政工程、钢厂、水泥厂、机器人、轨道交通等多个行业。

作为PACSystems RX3i系列的一部分,IC694ALG392模块与GE的其他工业自动化产品具有良好的兼容性和集成性。它可以轻松集成到现有的RX3i PACSystem中,为用户提供统一的编程和控制环境。

IC694ALG392模块与PLC、运动控制及人机界面(HMI)的编程结合到一个统一的环境,这种结合有助于减少学习周期和研发时间,提高生产效率。用户可以利用这种集成环境来轻松实现复杂的控制逻辑和自动化任务。

The GE US IC694ALG392 analog output module is a key component in the PACSystems RX3i series produced by General Electric (GE). This module is designed specifically for industrial automation and has powerful analog output capabilities. It can convert digital signals into analog signals for precise control of external devices or systems. The following is a detailed analysis of the module:

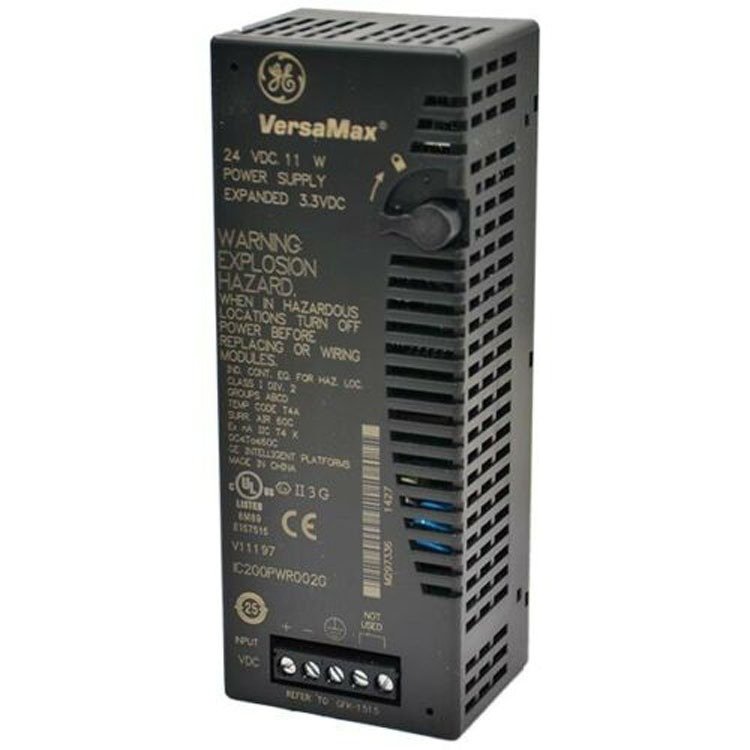

essential information

Model: IC694ALG392

Brand: GE (General Electric)

Series: PACSystems RX3i

Functional Features

Analog output:

The main function is to convert digital signals into analog signals for output, supporting voltage and current output.

The output types include voltage (such as 0 V to+10 V, -10 V to+10 V) and current (such as 0-20 mA, 4-20 mA).

Multi channel design:

It has 8 single ended output channels, each of which can independently control an analog signal.

This design enables the module to simultaneously control multiple external devices, improving the flexibility and efficiency of the system.

High precision and fast response:

The resolution can reach up to 16 bits (or up to 15 bits in some configurations), ensuring high output accuracy.

Each channel is updated separately within an 8-millisecond (ms) interval, ensuring fast response capability.

Internal fault detection:

When operating in current mode, it has internal fault detection function, such as disconnection fault detection.

This helps users and maintenance personnel to promptly identify and address potential wiring issues.

Maintain functionality:

Support maintaining the last known value interrupt of system power to prevent unexpected system behavior.

Application scope

The IC694ALG392 analog output module is widely used in the field of industrial automation, especially in systems that require precise control of analog output. It has been successfully applied in various industries such as CNC machinery, metallurgy, oil and gas, paper and printing, textile printing and dyeing, electronic manufacturing, automobile manufacturing, tobacco, plastic machinery, power plants, water treatment/environmental protection, municipal engineering, steel mills, cement plants, robots, rail transit, etc.

technical parameter

Working voltage: usually powered by external sources, ranging from 20 to 30 volts direct current (VDC), ideally 24 VDC.

Current consumption: The current consumption may vary depending on the power supply method. For example, when connected to a PLC backplane, it may be 110 mA @ 5 VDC, while when powered from an external 24 VDC power source, it may be 315 mA.

Update rate: The update rate for each channel is 8 ms.

Compatibility and Integration

As part of the PACSystems RX3i series, the IC694ALG392 module has good compatibility and integration with other industrial automation products from GE. It can be easily integrated into existing RX3i PACSystem, providing users with a unified programming and control environment.

Programming environment

The IC694ALG392 module is integrated with PLC, motion control, and human-machine interface (HMI) programming into a unified environment, which helps reduce learning cycles and development time, and improve production efficiency. Users can easily implement complex control logic and automation tasks using this integrated environment.

18030183032