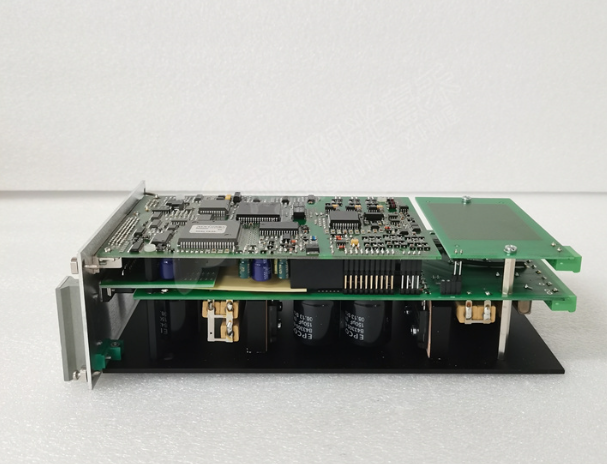

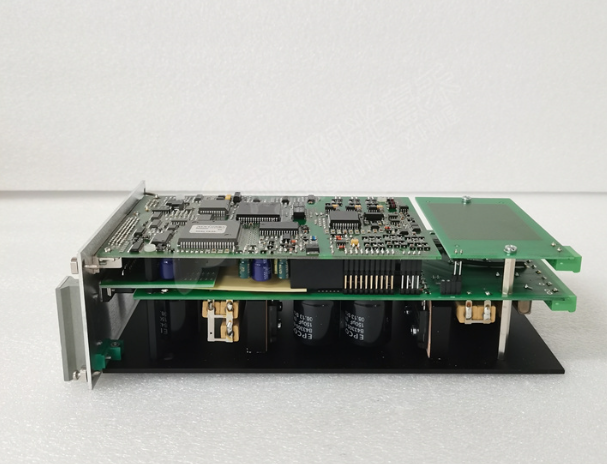

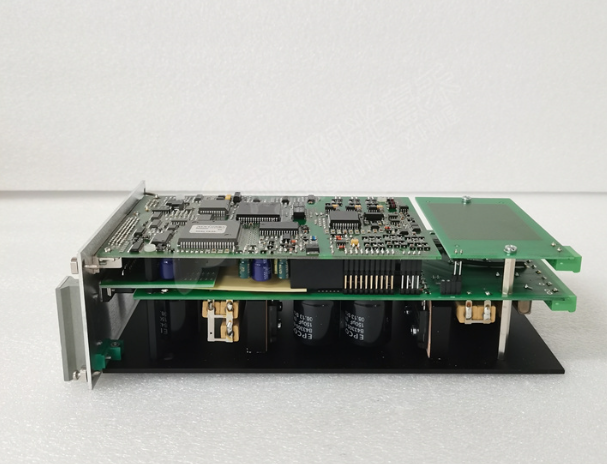

NOVOTRON ND32-5610伺服驱动器是一款专为控制伺服电机而设计的高性能产品,它在多个方面表现出色,以下是对该伺服驱动器的详细介绍:

The NOVOTRON ND32-5610 servo drive is a high-performance product designed specifically for controlling servo motors. It performs well in multiple aspects, and the following is a detailed introduction to the servo drive:

1、 Product Features

High precision motion control:

The NOVOTRON ND32-5610 servo drive provides extremely high control accuracy, ensuring that the servo motor moves in a very accurate manner to meet various precision control requirements.

Wide range of application areas:

Due to its excellent motion performance and stability, this servo drive is suitable for various industrial applications, including but not limited to mechanical manufacturing, automated production lines, robotics technology, precision instrument manufacturing, etc.

Flexible configuration and programming:

Usually supports multiple configuration options and programming methods, allowing users to flexibly set and adjust according to specific application needs.

Powerful protection function:

Equipped with comprehensive protection functions such as overcurrent protection, undervoltage protection, over temperature protection, etc., to ensure the safe and stable operation of the system.

Easy to integrate and maintain:

Equipped with standard communication interfaces and connection methods, it facilitates integration with other devices and control systems. Meanwhile, its modular design also makes maintenance and upgrades easier.

2、 Performance characteristics

Servo control: designed to control servo motors and provide high-precision motion control.

High resolution position control: capable of achieving precise position adjustment to meet high-precision job requirements.

Dynamic response capability: Quickly respond to external commands to ensure the timeliness and accuracy of motor movement.

Load adaptability: able to adjust according to different load conditions to ensure the stable operation of the system.

3、 Application Fields

Mechanical manufacturing: Achieving precise position and speed control in mechanical equipment such as CNC machine tools and machining centers.

Automated production line: Improve production efficiency and product quality on automated assembly, packaging, handling, and other production lines.

Robot technology: In industrial robots, precise path planning and motion control are achieved to improve the accuracy and efficiency of robot operations.

Precision instrument manufacturing: Ensure the accuracy and stability of precision equipment such as optical instruments and medical devices during the manufacturing process.

18030183032