TRICONEX是Invensys集团(现属于Schneider Electric)下属的一家安全仪表系统厂家,专门制造TRICON安全仪表SIS系统、ESD系统等。TRICONEX 3720是该公司的一款产品,具体为一个模拟输入模块。至于英维思SIS模块、冗余系统以及通信控制模块的具体优势特点、应用场景和产品介绍,目前无法提供确切的信息。但以下是对TRICONEX公司和其产品的简要介绍:

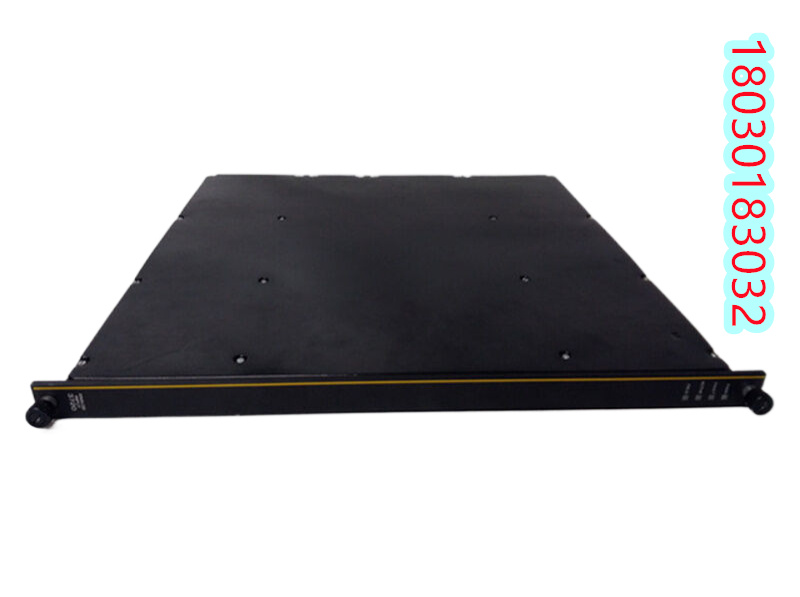

TRICON系统支持数字的和模拟的输入与输出点,以及热电偶输入和多种通讯能力。它有三种型式的机架:主机架、扩展机架、和远程机架。一个TRICON系统可以最多包含十五个机架,用以容纳各安装种输入、输出和热插备用模块,以及通讯模块等的适当的组合。此外,TRICONEX公司提供了多种产品,如TRICONEX 3721、TRICONEX 3503E、TRICONEX 3624等,以满足不同的应用需求。

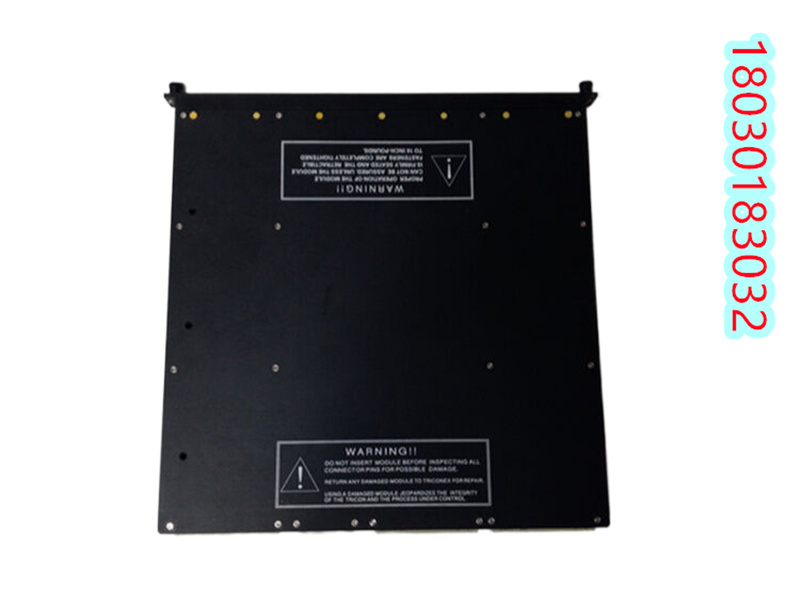

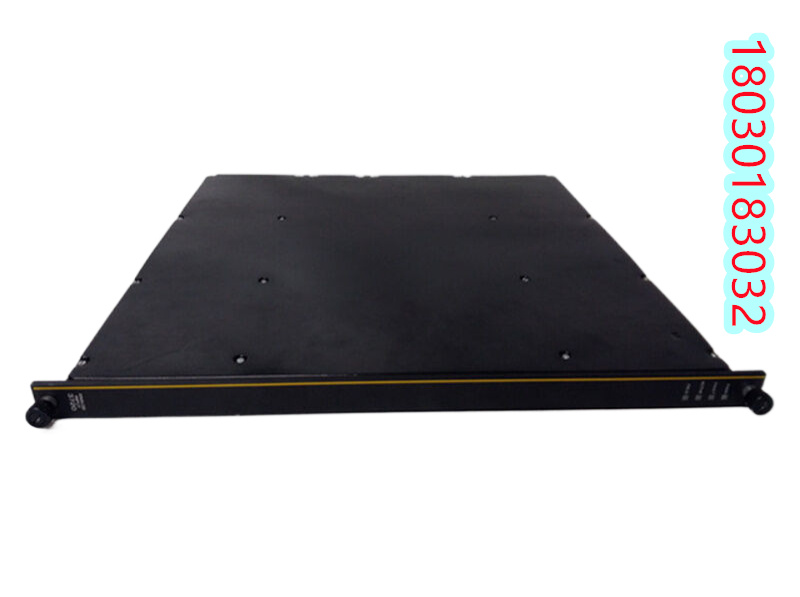

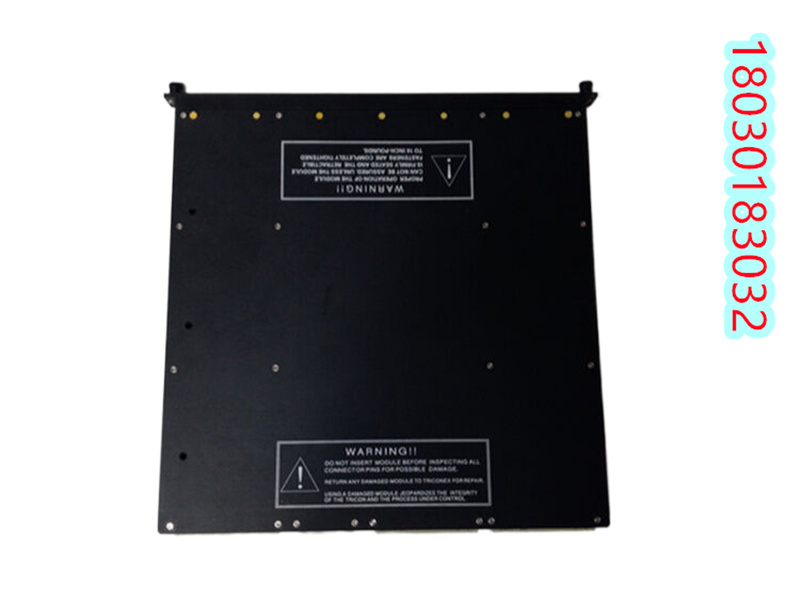

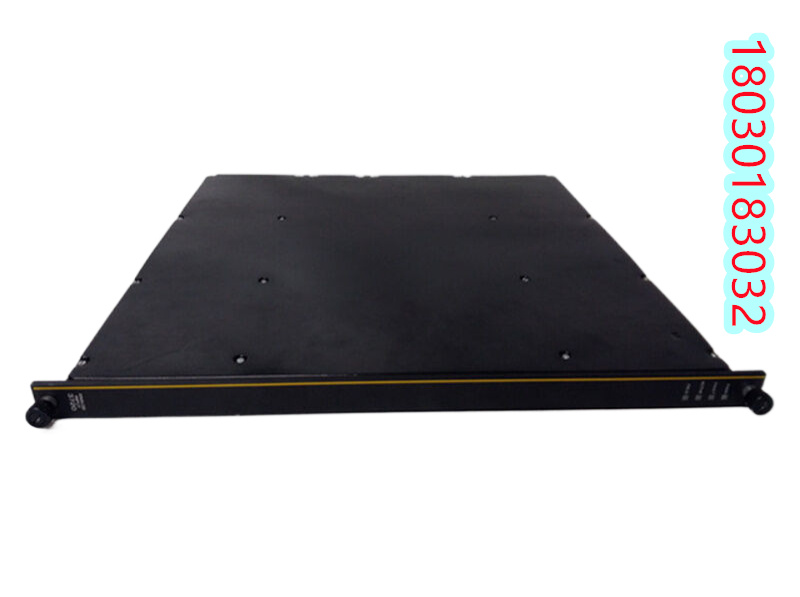

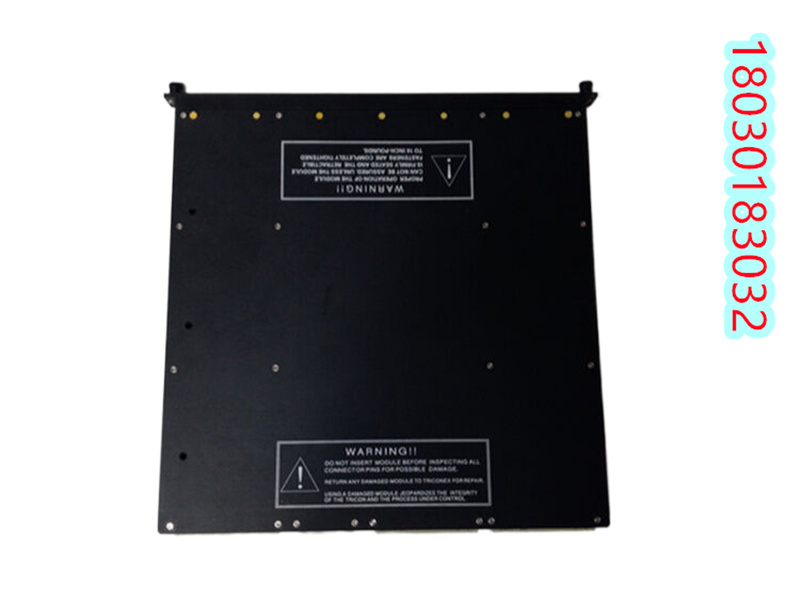

对于TRICONEX 3720模块,作为模拟输入模块,它可能具有高精度、稳定性好、可靠性高等特点。它可以接收模拟信号,并将其转换为数字信号,以供TRICON系统进行处理和控制。这种模块可能广泛应用于需要接收和处理模拟信号的工业自动化系统中。

至于冗余系统和通信控制模块的具体信息,冗余系统通常是为了提高系统的可靠性和稳定性,当主系统出现故障时,冗余系统可以接管并继续运行,从而保证系统的连续运行。通信控制模块则可能负责与其他设备或系统进行通信,以实现数据的交换和控制指令的传输。

TRICONEX is a safety instrument system manufacturer under the Invensys Group (now part of Schneider Electric), specializing in the manufacture of TRICON safety instrument SIS systems, ESD systems, etc. TRICONEX 3720 is a product of the company, specifically an analog input module. As for the specific advantages, application scenarios, and product introductions of the Envision SIS module, redundant system, and communication control module, exact information cannot be provided at present. But here is a brief introduction to TRICONEX company and its products:

The TRICON system supports digital and analog input and output points, as well as thermocouple inputs and various communication capabilities. It has three types of racks: main rack, expansion rack, and remote rack. A TRICON system can contain up to fifteen racks to accommodate appropriate combinations of various types of input, output, and hot plug backup modules, as well as communication modules. In addition, TRICONEX offers a variety of products, such as TRICONEX 3721, TRICONEX 3503E, TRICONEX 3624, etc., to meet different application needs.

For the TRICONEX 3720 module, as an analog input module, it may have the characteristics of high precision, good stability, and high reliability. It can receive analog signals and convert them into digital signals for processing and control by the TRICON system. This type of module may be widely used in industrial automation systems that require receiving and processing analog signals.

As for the specific information of redundant systems and communication control modules, redundant systems are usually designed to improve the reliability and stability of the system. When the main system fails, the redundant system can take over and continue to operate, ensuring the continuous operation of the system. The communication control module may be responsible for communicating with other devices or systems to achieve data exchange and transmission of control instructions.

18030183032