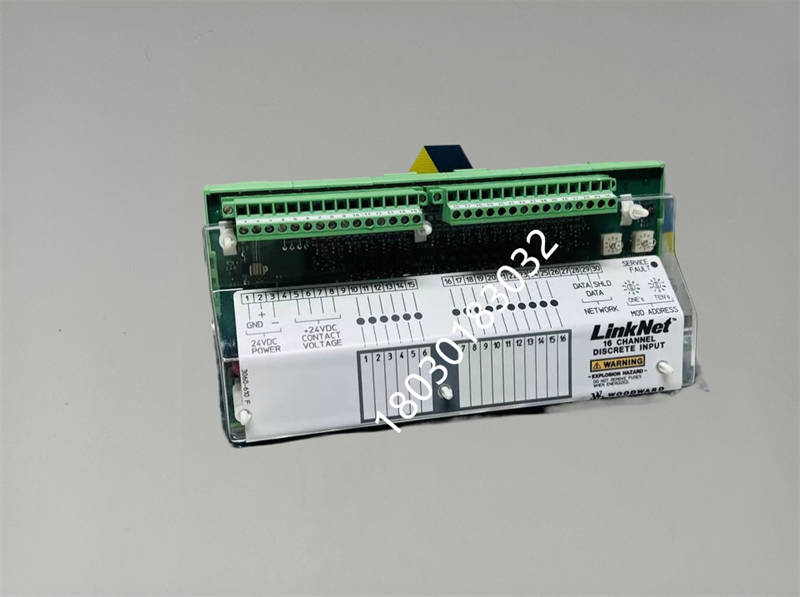

Woodward 9905-972 伍德沃德速度控制器是伍德沃德(Woodward)公司推出的一款高性能速度控制设备,专为工业领域设计,广泛应用于发电、燃气轮机、蒸汽轮机及柴油机等动力系统的速度控制与负载分配。

产品特点

高精度控制

采用先进的数字控制技术,能够实现对动力系统速度的精确调节,确保系统稳定运行。

支持高精度传感器输入,适应复杂工况下的速度控制需求。

灵活的负载分配功能

支持多机并联运行时的负载均衡,优化系统效率,减少单机过载风险。

可根据系统需求动态调整负载分配策略,提升整体运行可靠性。

模块化设计

模块化结构便于安装、维护和升级,降低维护成本。

支持多种通信接口,易于与现有控制系统集成。

环境适应性强

工作温度范围广,适应恶劣工业环境。

防护等级高,具备抗振动、抗冲击能力,确保长期稳定运行。

用户友好界面

提供直观的操作界面和丰富的诊断功能,便于用户实时监控系统状态。

支持参数配置和故障诊断,简化运维流程。

技术参数

输入信号:支持模拟量(4-20mA、0-10V)和数字量输入。

输出信号:模拟量输出(4-20mA)、继电器输出。

控制精度:±0.1%(具体精度取决于应用场景)。

通信接口:支持Modbus、Profibus等工业通信协议。

环境温度:-20°C 至 +70°C(具体范围可能因型号而异)。

应用领域

发电系统:用于燃气轮机、蒸汽轮机及柴油发电机组的速度控制和负载分配。

工业驱动:适用于泵、风机、压缩机等工业设备的速度调节。

船舶动力:用于船舶主推进系统和辅助设备的速度控制。

分布式能源:支持微电网和分布式能源系统的功率平衡与控制。

优势

可靠性高:伍德沃德在动力控制领域拥有超过百年的技术积累,产品经过严格测试,适用于高要求的工业应用。

节能高效:通过精确的速度控制和负载分配,优化系统效率,降低能耗。

全球支持:伍德沃德提供全球技术支持与服务,确保用户在使用过程中获得及时帮助。

应用案例

发电厂:在燃气轮机或蒸汽轮机发电系统中,9905-972控制器用于实现多机并联运行的负载均衡,确保电网稳定。

船舶动力:在船舶推进系统中,控制器用于调节主机速度,优化航行性能。

工业驱动:在压缩机、泵等工业设备中,控制器用于实现精确的速度控制,提升设备运行效率。

注意事项

在安装和使用前,请仔细阅读产品手册,确保符合系统要求。

定期检查控制器运行状态,及时更新固件以获得最新功能。

如需定制化功能,可联系伍德沃德技术支持团队进行配置。

Woodward 9905-972 速度控制器凭借其高精度控制、灵活的负载分配功能及可靠的性能,广泛应用于各类工业动力系统中,是提升系统效率与稳定性的理想选择。

Woodward 9905-972 Woodward Speed Controller is a high-performance speed control device launched by Woodward Corporation, designed specifically for the industrial field and widely used in speed control and load distribution of power systems such as power generation, gas turbines, steam turbines, and diesel engines.

Product Features

high precision control

By adopting advanced digital control technology, precise adjustment of the power system speed can be achieved to ensure stable operation of the system.

Supports high-precision sensor input and adapts to speed control requirements under complex working conditions.

Flexible load distribution function

Support load balancing when multiple machines are running in parallel, optimize system efficiency, and reduce the risk of single machine overload.

The load distribution strategy can be dynamically adjusted according to system requirements to improve overall operational reliability.

Modular design

The modular structure facilitates installation, maintenance, and upgrading, reducing maintenance costs.

Supports multiple communication interfaces and is easy to integrate with existing control systems.

Strong environmental adaptability

Wide working temperature range, suitable for harsh industrial environments.

High protection level, with anti vibration and anti impact capabilities, ensuring long-term stable operation.

User friendly interface

Provide an intuitive user interface and rich diagnostic functions to facilitate real-time monitoring of system status by users.

Support parameter configuration and fault diagnosis, simplify operation and maintenance processes.

Technical Parameter

Input signal: Supports analog (4-20mA, 0-10V) and digital input.

Output signals: analog output (4-20mA), relay output.

Control accuracy: ± 0.1% (specific accuracy depends on the application scenario).

Communication interface: Supports industrial communication protocols such as Modbus and Profibus.

Environmental temperature:- 20 ° C to+70 ° C (specific range may vary by model).

application area

Power generation system: used for speed control and load distribution of gas turbines, steam turbines, and diesel generator sets.

Industrial drive: suitable for speed regulation of industrial equipment such as pumps, fans, compressors, etc.

Ship power: used for speed control of the main propulsion system and auxiliary equipment of a ship.

Distributed energy: supports power balance and control of microgrids and distributed energy systems.

advantage

High reliability: Woodward has over a hundred years of technical accumulation in the field of power control, and its products have undergone rigorous testing and are suitable for high demand industrial applications.

Energy saving and efficient: By precise speed control and load distribution, optimize system efficiency and reduce energy consumption.

Global Support: Woodward provides global technical support and services to ensure that users receive timely assistance during use.

Application Cases

Power plant: In gas turbine or steam turbine power generation systems, the 9905-972 controller is used to achieve load balancing for multi turbine parallel operation, ensuring grid stability.

Ship power: In ship propulsion systems, controllers are used to adjust the speed of the main engine and optimize navigation performance.

Industrial drive: In industrial equipment such as compressors and pumps, controllers are used to achieve precise speed control and improve equipment operating efficiency.

precautions

Before installation and use, please carefully read the product manual to ensure compliance with system requirements.

Regularly check the operation status of the controller and update the firmware in a timely manner to obtain the latest features.

If customized features are required, please contact the Woodward technical support team for configuration.

The Woodward 9905-972 speed controller is widely used in various industrial power systems due to its high-precision control, flexible load distribution function, and reliable performance, making it an ideal choice for improving system efficiency and stability.

| ABB | DI818 |

| ABB | DO818 |

| ABB | AI820 |

| BASLER | A404K |

| BENTLY | 170180-02-05 |

| BENTLY | 170180-01-05 |

| BENTLY | 170180-01-00 |

| BENTLY | 1034549-20 |

| BENTLY | 1034549-6 |

| WOODWARD | WOODWARD TM25LP |

| WOODWARD | WOODWARD9907-164 |

| SST | 5136-PFB-104 |

| LAM | 810-107813-105 |

| LAM | 810-064624-521 |

| LAM | 810-066590-004 |

| EtherWAN | EMC400-Epws |

| BRAD | PC104-DPIODRL-DPM-BKF |

| FOXBORO | FCP280RH924YA |

| ABB | ACS800-04-0210-3+E210+P901停产替代 ACS880-01-293A-3+E200 |

18030183032