WOODWARD 9907-167是一种汽轮机数字调速器,用于控制汽轮机的转速,以实现船舶的前进和停止。它是汽电联产、发电厂等工业领域中常用的控制设备之一。

WOODWARD 9907-167汽轮机数字调速器通过采集汽轮机的转速信号,根据预设的控制逻辑和参数,自动调节汽轮机的进气量、排气量等参数,以实现汽轮机的稳定运行和输出功率的精确控制。它具有高精度、高稳定性、快速响应等特点,能够适应不同的汽轮机型号和运行环境。

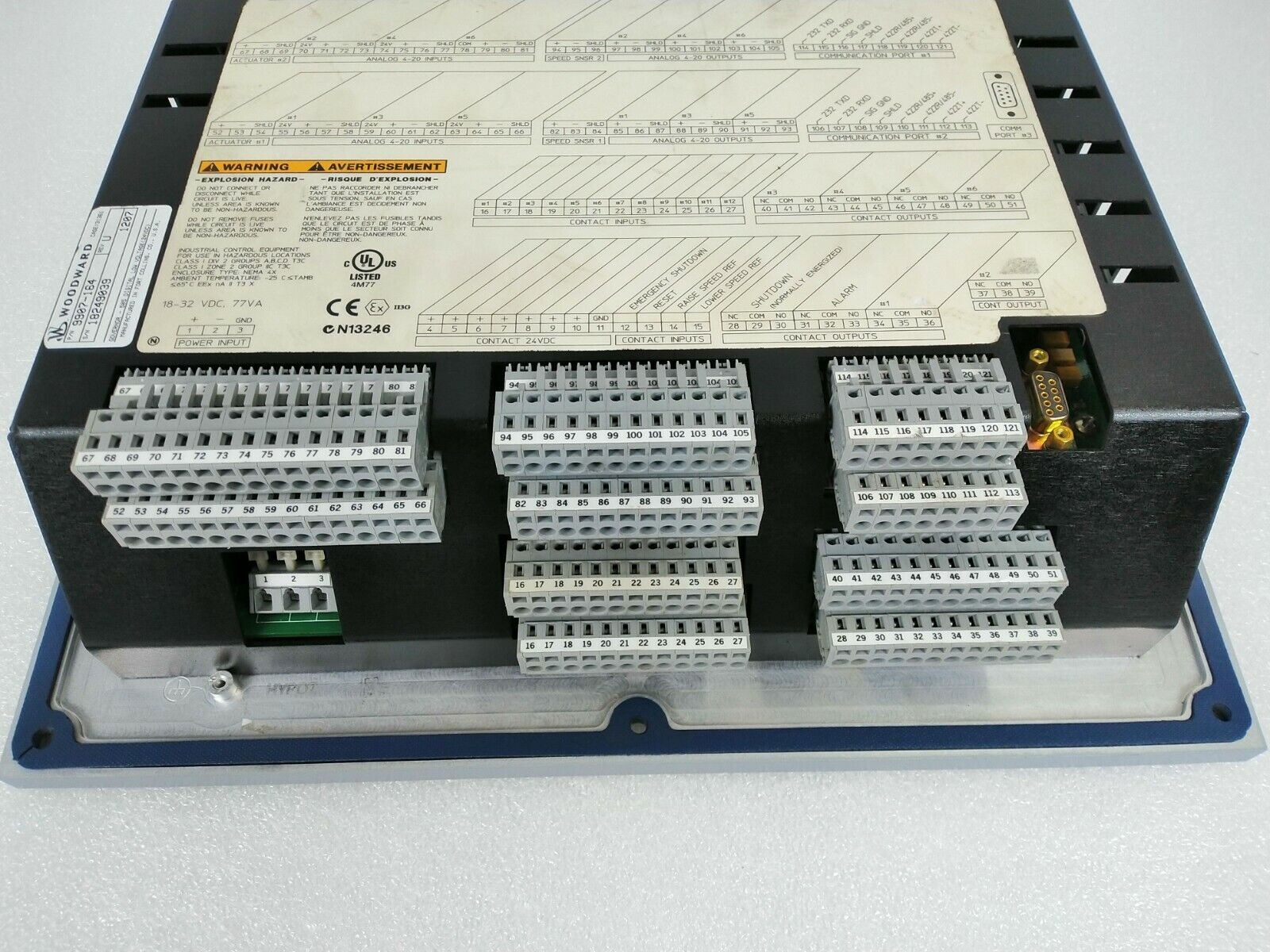

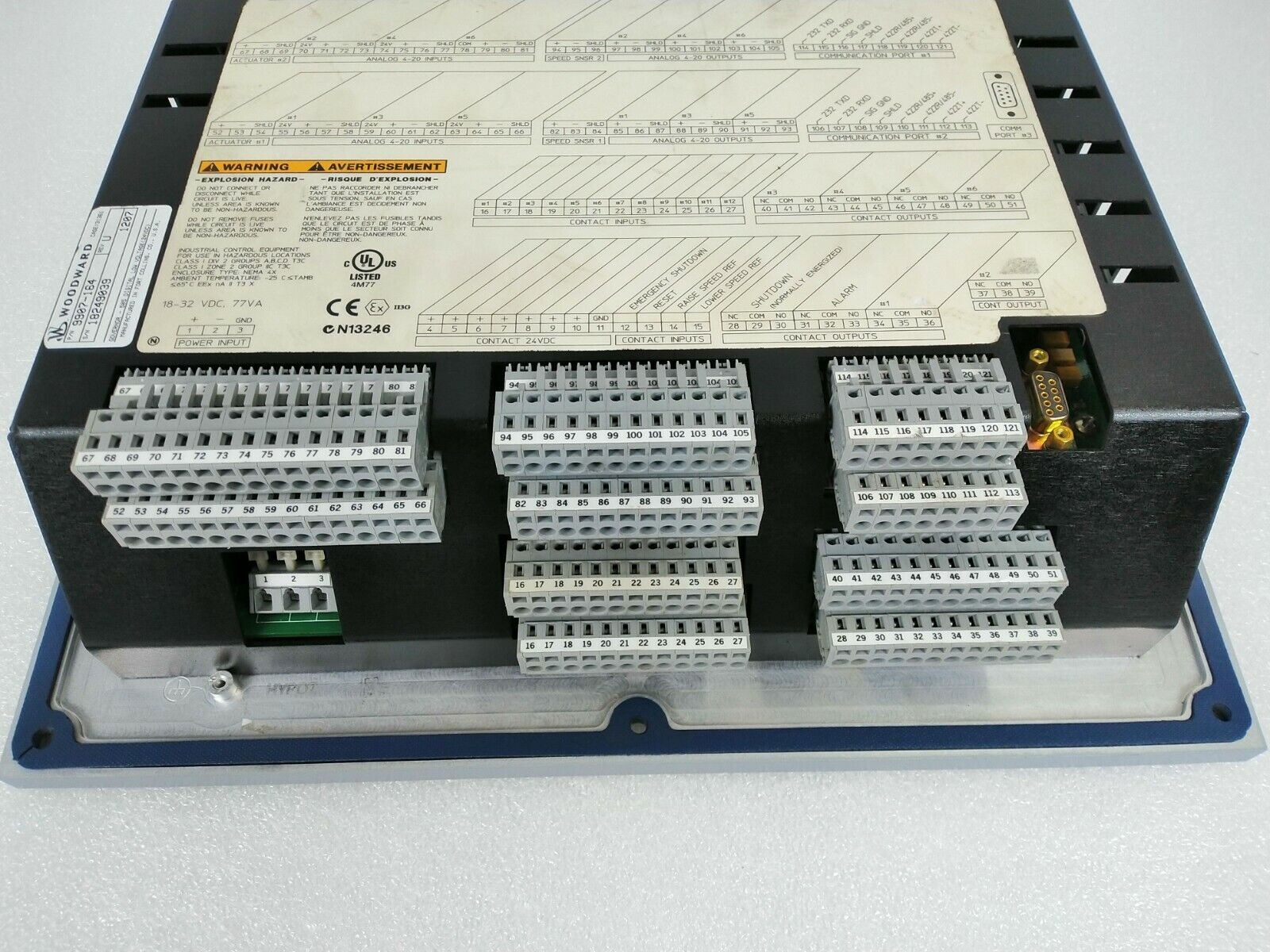

使用WOODWARD 9907-167汽轮机数字调速器时,需要根据具体的工业应用场景进行配置和控制程序的编写。通常需要连接传感器和执行器,设置通讯接口和参数,编写控制程序,并将程序下载到调速器中。在运行时,调速器将根据实际的控制需求进行自动调节和稳定控制,以确保汽轮机的正常运行和输出功率的精确控制。

总之,WOODWARD 9907-167汽轮机数字调速器是一种重要的工业控制设备,广泛应用于汽电联产、发电厂等工业领域中。它可以提高汽轮机的运行效率和稳定性,同时降低操作人员的劳动强度和出错率,为工业自动化控制系统的稳定运行提供重要保障。

WOODWARD 9907-167伍德沃德汽轮机数字调速器的使用方法包括以下步骤:

需要注意的是,在使用WOODWARD 9907-167伍德沃德汽轮机数字调速器时,应遵循相关的安全规范和操作指南,确保系统的稳定性和安全性。同时,根据具体的工业应用场景和实际需求,可能还需要进行额外的配置和控制优化。

WOODWARD 9907-167 is a steam turbine digital governor used to control the speed of the steam turbine to achieve the forward and stop of the ship. It is one of the commonly used control equipment in steam and power generation, power plant and other industrial fields.

WOODWARD 9907-167 Steam turbine digital governor by collecting the speed signal of the steam turbine, according to the preset control logic and parameters, automatically adjust the gas intake, exhaust and other parameters of the steam turbine, in order to achieve the stable operation of the steam turbine and the accurate control of the output power. It has the characteristics of high precision, high stability and fast response, and can adapt to different types of steam turbines and operating environments.

When WOODWARD 9907-167 turbine digital governor is used, the configuration and control program need to be written according to the specific industrial application scenario. It is usually necessary to connect the sensor and the actuator, set the communication interface and parameters, write the control program, and download the program to the governor. During operation, the governor will automatically adjust and stabilize according to the actual control requirements to ensure the normal operation of the turbine and the accurate control of the output power.

In short, WOODWARD 9907-167 steam turbine digital governor is an important industrial control equipment, widely used in steam and power generation, power plants and other industrial fields. It can improve the operation efficiency and stability of the steam turbine, and reduce the labor intensity and error rate of the operator, which provides an important guarantee for the stable operation of the industrial automation control system.

WOODWARD 9907-167 The use of the Woodward Turbine digital governor consists of the following steps:

Installation and connection: Install the governor to the control cabinet or operating platform near the steam turbine, and connect the sensor and actuator according to the instructions to ensure correct signal transmission and action execution.

Power supply and communication: Provide the required power supply for the governor, and use the appropriate communication interface to connect the governor to the upper computer or monitoring system. Ensure correct configuration and parameter Settings of communication interfaces.

Parameter setting: According to the turbine model, operation requirements and control system requirements, set the control parameters of the governor, such as target speed, start/stop speed, acceleration/deceleration, etc.

Control program writing: The use of supported programming languages (such as C++, C#, etc.) to write control programs, according to the actual control logic and algorithm to achieve the control and operation of the governor. Ensure the correctness and stability of the control program.

Program download and debugging: the written control program is downloaded to the governor, and debugging and testing are carried out to ensure that the governor can operate normally in accordance with the preset control logic and parameters, and can correctly respond to the state changes and operational requirements of the turbine.

Operation and maintenance: Start the steam turbine and control system and run the governor. During operation, it is necessary to pay close attention to the running state and parameter changes of the governor, and adjust and control the speed and output power of the turbine in time. At the same time, regular maintenance and maintenance is also an important measure to ensure the normal operation and service life of the governor.

It should be noted that when using the WOODWARD 9907-167 digital turbine governor, the relevant safety specifications and operating guidelines should be followed to ensure the stability and safety of the system. At the same time, depending on the specific industrial application scenarios and actual needs, additional configuration and control optimization may be required.

公司主营产品,优势供应,充足库存:

各品牌DCS.PLC备件:

(本特利):3500系统/3300系统,前置器探头等

德国EPRO MMS6000系统卡件MMS3000系统卡件PR6422 PR6423 PR6424 PR6426

PR9268等系列探头前置器备件.

ABB PLC系统模块DCS系统卡件,包括一些停产的控制系统模块卡性。

GE燃机卡件IS200系列,DS200系列

Rockwell Allen-Bradley:SLC500/1747/1746、MIcroLogIx/1761/1763/1762/1766/1764、

CompactLogIx/1769/1768.

LogIx5000/1756/1789/1794/1760/1788、PLC-5/1771/1785等。

Invensys Foxboro(福克斯波罗)∶I/A SerIes系统,FBM(现场输入/输出模块〕顺序控制、梯形逻辑拉制、事故迫忆处理、数模转换、

输入/输出信号处理、数据道信及处理等。

lnvensys TrIconex:元余容错控制系统、基于三重模件冗余(TMR〉结构的**现代化的容错控制器。

westInghouse(西屋):OVATION系统.WDPF系统.WEStatIon系统备件.

SchneIder ModIcon(施耐德莫迪康):Quantum 140系列处理器、控制卡.电源模块等。

ABB:工业机器人备件DSQC系列、BaIley lNFI 90等。

Motorola(摩托罗拉):MVME5500、MVME6100、MVME 162、MVME 167、MVME1772、MVME177等系列。

XYCOM:I/O、VME板和处理器等。

GE FANUC(GE发那科):模块、卡件、驱动器等各类备件,IC693,IC695,IC697 IC698等系列。

Yaskawa(安川:伺吸控制器、伺服马达、问吸驱动器。

Bosch Rexroth(博世力士乐):Indramat,l/O模块,.PLC控制器,驱动模块等。

Woodward(伍德沃德):SPC阀位控制器、PEAK150数字控制器。

Rosemount罗斯豢特:压力变送器、流量计。

18030183032